Langfang Chaochen Thermal Insulation Materials Co., Ltd., located in the Beijing-Tianjin Corridor, is located in Langfang City, which is known as the “Green Building Capital”. It is adjacent to Tianjin in the east and Beijing in the west. Expressway, railway, high-speed rail, aviation and other modes of transportation are convenient and fast, and logistics is convenient on time.....

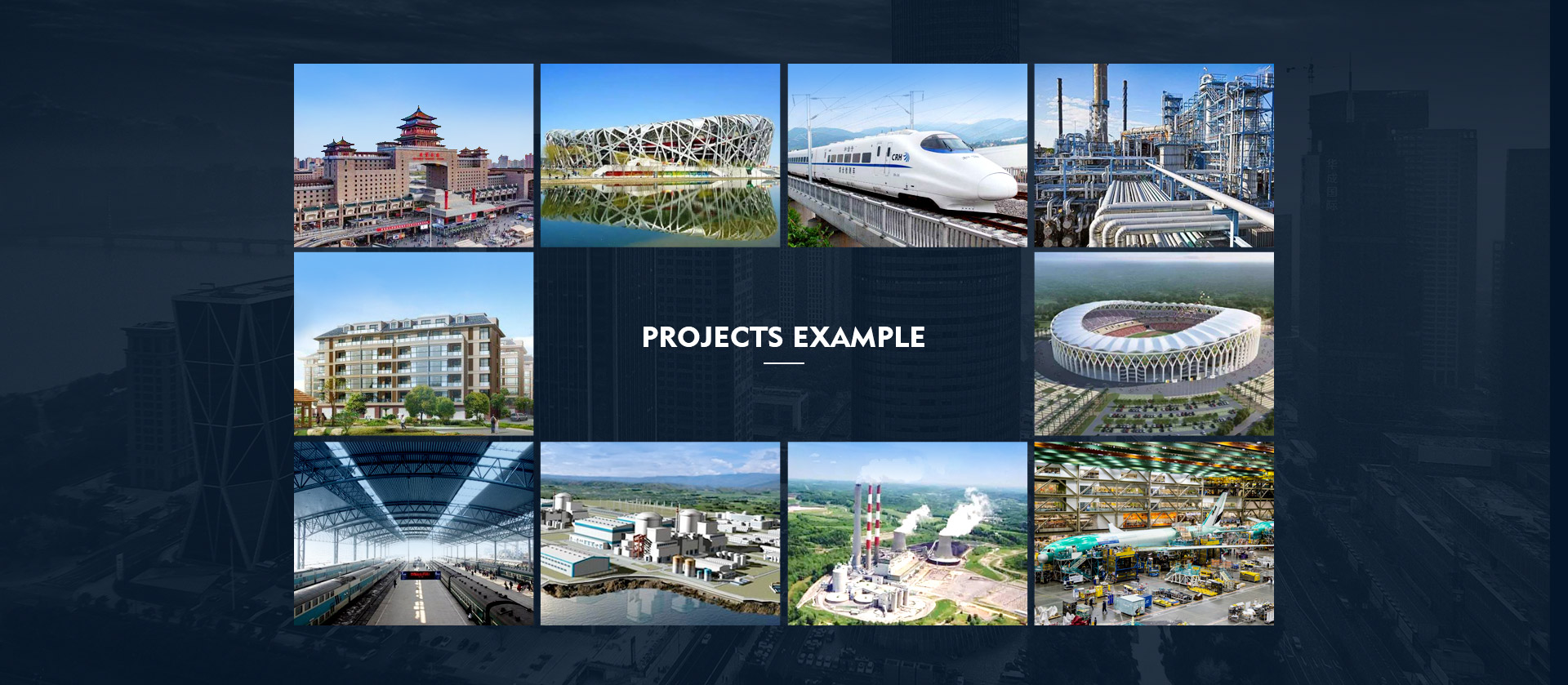

The company is a scientific and technological enterprise integrating production, sales, research and development and construction. Its main products include insulating refractory insulation materials, sound insulation and sound-absorbing materials, chemical materials and sealing materials, which are widely used in constructions and

20-Hour service

Honest delivery

Customized demand

Professional after-sale

news information